From Concept to Commercialization: How Shepherd Supports Custom Catalyst Manufacturing

Tuesday, October 7, 2025

From clean energy to polymerization, catalysts quietly power the chemical reactions that shape our world. But creating the right catalyst for a unique process requires more than off-the-shelf chemistry—it takes a partner who can scale your vision from lab to production.

At Shepherd Chemical, we specialize in custom catalyst development, offering customers the ability to co-develop tailored catalyst systems from concept to commercialization.

Shepherd’s End-to-End Support Model

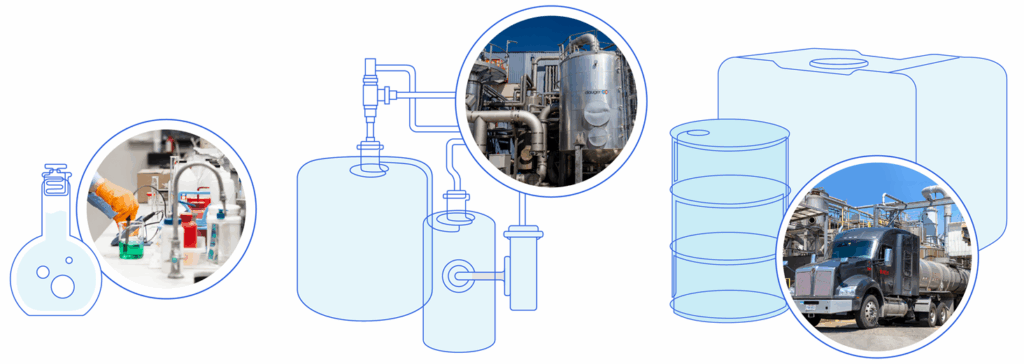

Whether you’re an R&D team looking to optimize performance or a manufacturer needing process scalability, we offer support at every step:

- Early-Stage Design & Feasibility

Collaborate with our technical team to evaluate catalyst viability, including thermodynamic modeling and precursor selection. - Pilot Production

We offer pilot-scale synthesis to validate performance before commercial runs, reducing technical risk. - Process Optimization

Improve yield, stability, and downstream process compatibility with help from our experienced team. - Full-Scale Manufacturing

With robust global manufacturing capabilities, we can support custom catalyst production at commercial scale with quality and consistency.

Why Catalyst Projects Succeed at Shepherd

- Deep knowledge of metal-organic precursors and complex inorganic chemistries

- Collaborative approach with full IP protection

- Integrated R&D and manufacturing teams

- Proven track record of helping customers scale breakthroughs

From polymer production to environmental remediation, our custom catalyst work helps drive performance and innovation in some of the world’s most critical sectors.

Partner with Us on Your Next Catalyst Challenge

When it comes to catalyst manufacturing, there’s no one-size-fits-all. But there is a right partner.

If you’re seeking a trusted ally in custom catalyst development, Shepherd’s co-development team is ready to support your success—at every stage.