OUR PATH TO A

BRIGHTER FUTURE

Annual Sustainability Report

Published in 2025

About Shepherd

The Shepherd Chemical Company is a fourth-generation, family-owned company that develops and manufactures metal-based chemistry for the global marketplace. Shepherd’s core purpose is Creating Value that Brightens Lives. Its specialty chemicals are essential to technologies for consumer safety, environmental sustainability, advanced product performance, and industrial process efficiency.

Partnering with industries from airbags and tires to fragrance and personal care, from industrial components and polyurethanes to lubricants and catalysts, Shepherd collaborates on both standard and custom co-developed metal chemistry. Shepherd has a passion for innovation and over 100 years of expertise working with customers from initial concept to packaged product.

Shepherd operates three manufacturing plants in North America and Europe, manages sales and distribution offices worldwide, and every day more than 250 employees pursue Shepherd’s core purpose.

SHEPHERD CHEMICAL EXISTS TO CREATE VALUE THAT BRIGHTENS LIVES BY

- Providing World Class Customer Service

- Being a Great Place to Work

- Positively Impacting Communities and Society

- Achieving Long-Term Profitable Growth

About the Report

This report demonstrates Shepherd’s long-term responsibility for, and commitment to Our Company, Our Customers, Our Community, and Our Environment. Building on Shepherd’s century-long history of responsible stewardship, customer service, and groundbreaking innovation, Shepherd is ushering in a new era of sustainability leadership. The company will transparently share with all stakeholders its commitments, demonstrate progress, showcase innovation, and highlight the amazing Shepherd team.

The Sustainability Strategy is built on three pillars: Conserve, Protect, and Contribute. For each pillar, the objective is to highlight the most significant sustainability topics. Conserve focuses on improving resource and energy use. Protect captures the company’s commitment to making a positive impact on people and the environment. Contribute showcases Shepherd’s engagement with the community, investment in employee wellness, and ability to create innovative, sustainable chemistries that Brighten Lives.

In this report, you will find sections dedicated to each of the three pillars, including commitments, data reporting, certifications, alignment with the United Nations Sustainable Development Goals, Shepherd’s Ecovadis rating, and various highlights from across the organization.

Except where otherwise mentioned, the data in this report includes US Operations.

You are invited to join Shepherd in the next chapter of a longstanding commitment to Creating Value that Brightens Lives.

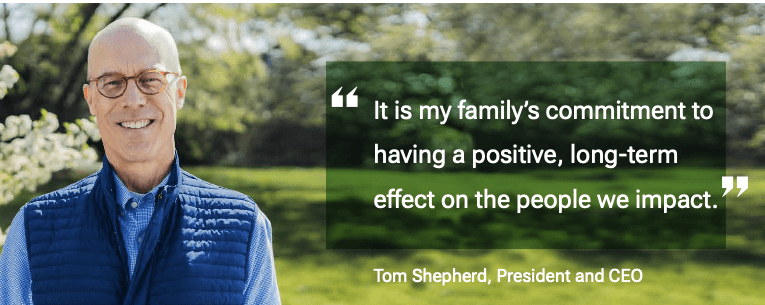

A Message From our CEO About Sustainability

Our Core Purpose

Shepherd Material Science exists solely for the purpose of Creating Value that Brightens Lives. This is our “Core Purpose” and a reflection of my family’s commitment to having a positive long-term effect on the people we impact. “Whose lives?” one might wonder. Specifically, those of our customers, our team members, our neighbors, society in general, and our shareholders. Value for each of these constituencies means delivering more benefit than their best alternative while being good stewards of the environment and the earth’s resources. We are very intentional about this.

- For customers value includes quality products reliably delivered at prices that provide the most value, PLUS a technically expert partner with whom they can co-develop their own value creating, sustainability enhancing products.

- For our team members (of which I am one) value includes good and reliable pay and benefits, a place where we belong, a safe and fulfilling work experience, and a purpose of which we are proud.

- For our neighbors value includes attractive jobs, community leadership and philanthropic assistance, clean water and air, and tax revenues that support local governments.

- For society in general value includes good for the world end-products such as automotive air bags, energy efficient buildings, and more recyclable plastics, the efficient use of resources, and the absence of detrimental elements such as pollution, waste, and corruption.

- For our shareholders value includes persistent acceptable returns on investment, deep and long relationships with those listed above, and the knowledge that we are creating value that brightens lives and contributing to a better, more sustainable world.

Sustainability Roadmap

Shepherd Material Science is committed to pursuing innovations that simultaneously brighten the lives of all constituents. While such

innovations are rarely easy to find and often difficult to carry out, they can be profoundly sustainable and productive when realized. Recent

successes include product and process innovations that simultaneously use less energy, generate less waste, are less challenging to produce, and enable the development of our customers’ own sustainability innovations.

- We will continue to establish meaningful sustainability goals and strategies in the areas of safety, belonging, product stewardship, water and energy usage, water and air emissions, and community

outreach. - We are committed to understanding and reporting each operating company’s scope 1 and 2 greenhouse gas emissions and to developing appropriate improvement targets.

- We will pursue these ends at a pace that creates value, aiming each day to be more sustainable than we were the day before.

- As requests for sustainability reports are vast and diverse, we are unable to respond to every inquiry in the manner requested. Instead, we have chosen to adopt pertinent sustainability standards at each operating company and maintain a vital few internal improvement metrics to be shared with customers and other stakeholders.

conserve

We CONSERVE through conscientious sourcing for sustainable metal chemistry, and by minimizing waste and optimizing our use of resources through recycling, energy, and water conservation and responsible consumption and reduction of raw materials.

R&D and Operations Impact Categories

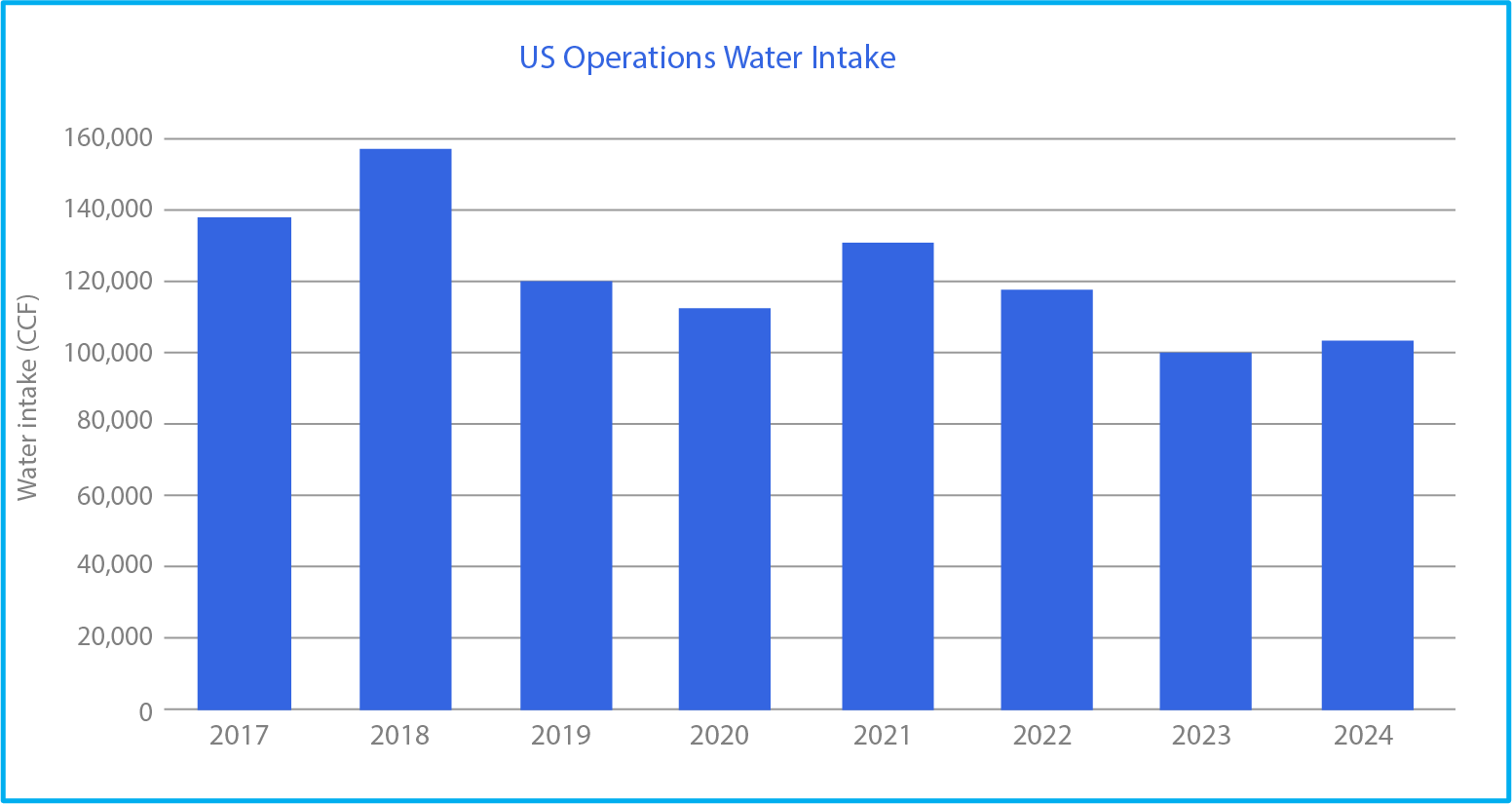

Water

Water stewardship is a priority at Shepherd. Opportunities to reduce water consumption are identified through process improvements, recovery, and recycling. These opportunities are assessed in an annual management review and planning process to evaluate and prioritize water reduction projects.

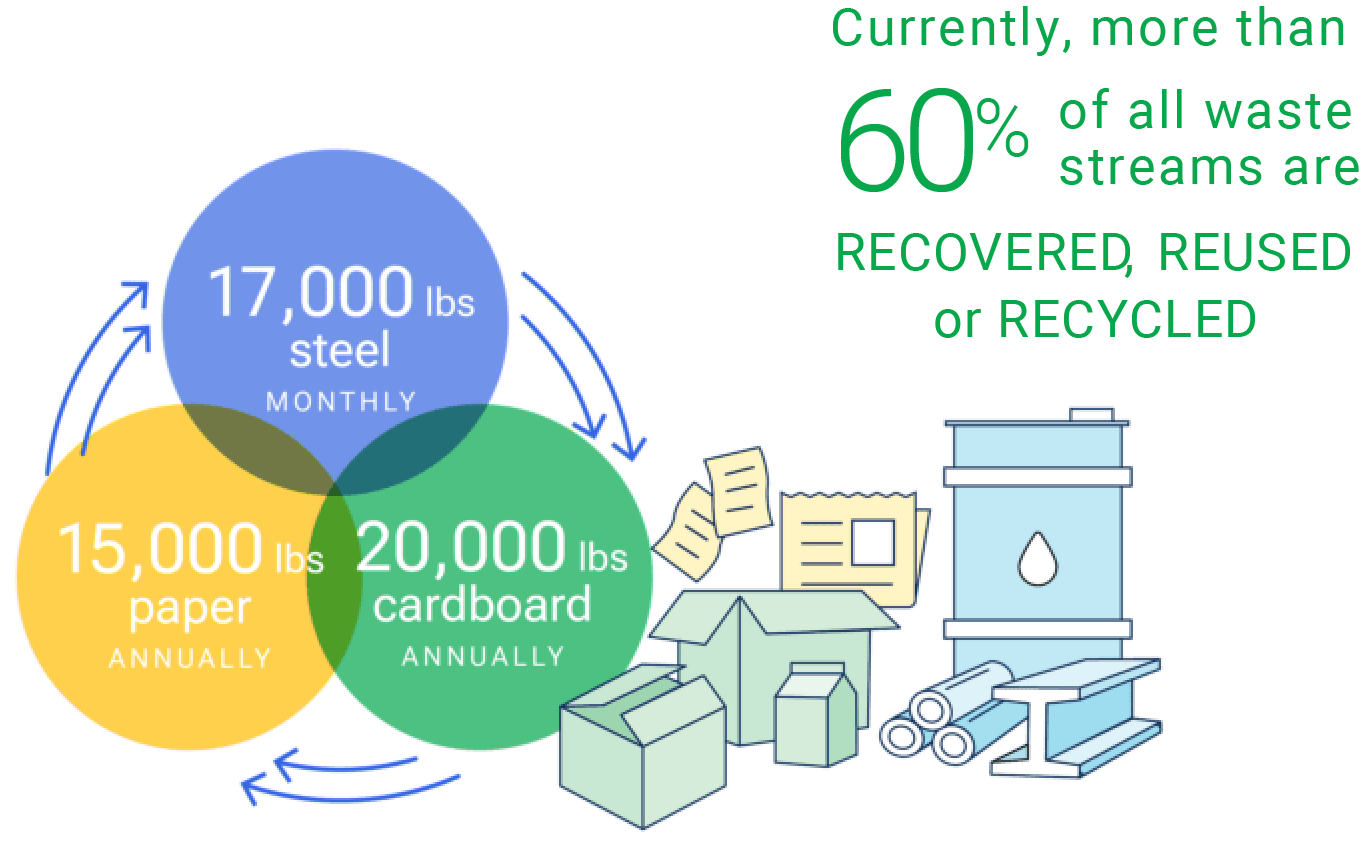

WASTE, EMISSIONS, & CIRCULARITY

Shepherd has a rich history filled with stories of delivering innovative solutions to customers. The R&D team is the catalyst and driving force behind these innovative outcomes. Shepherd’s New Product Development (NPD) process is an iterative and collaborative process to develop new products that are tailored to meet customers’ needs. The NPD process stage-gates ensure that the environmental and sustainability impacts of each project are analyzed. This includes safer chemistry reviews, circularity assessments, greenhouse gas (GHG) emission calculations, and identification of opportunities to reduce waste.

Across Shepherd’s operations, opportunities are identified and acted on to recycle packaging, equipment, and waste streams. One of Shepherd’s significant waste reduction activities is the reclamation of metals through wastewater treatment. Removing these materials from wastewater while simultaneously innovating to reduce waste from process units supports compliance efforts, reduces costs, and drives sustainability.

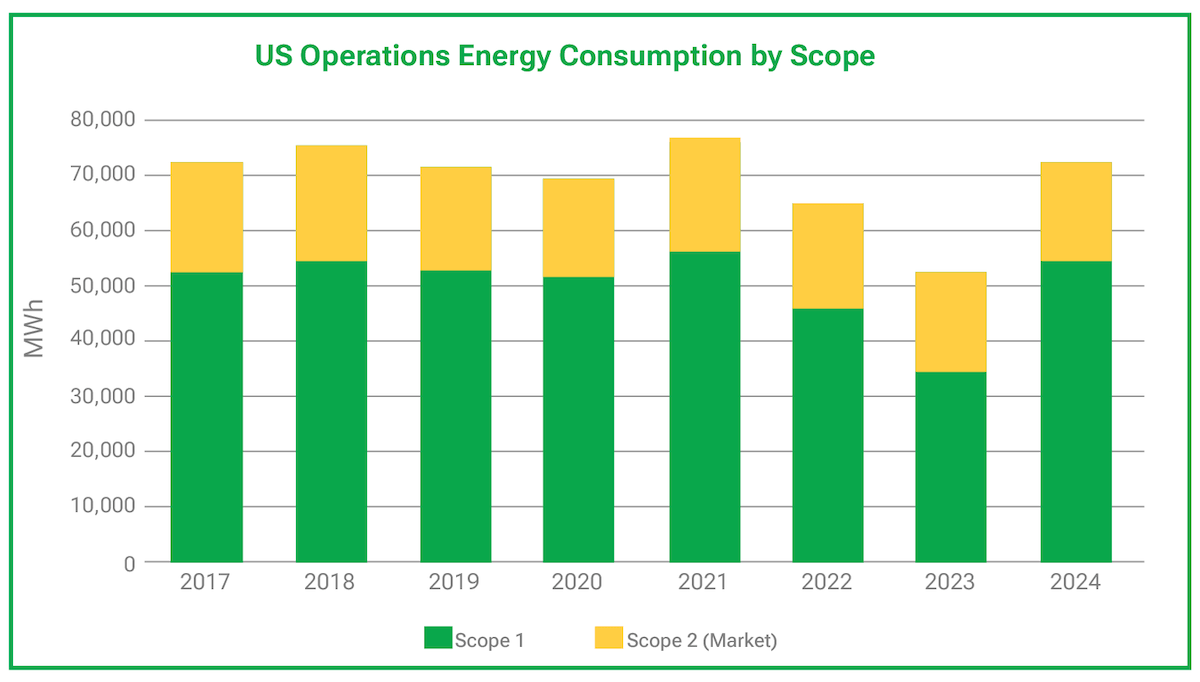

Energy

Shepherd seeks to improve the energy efficiency of site operations and fund projects to achieve such improvements. Existing product lines are prioritized for cross-functional innovation efforts. The prioritization process includes consideration of waste streams and energy consumption.

Product Stewardship

Shepherd always considers the risks of its products in the intended and designed application of their use. The company works to understand and communicate the hazards, risks, and appropriate risk controls to relevant stakeholders. The team at Shepherd continually monitors changes in regulations and available information on hazards and risks.

Process Innovation

INNOVATIVE NEW PROCESS

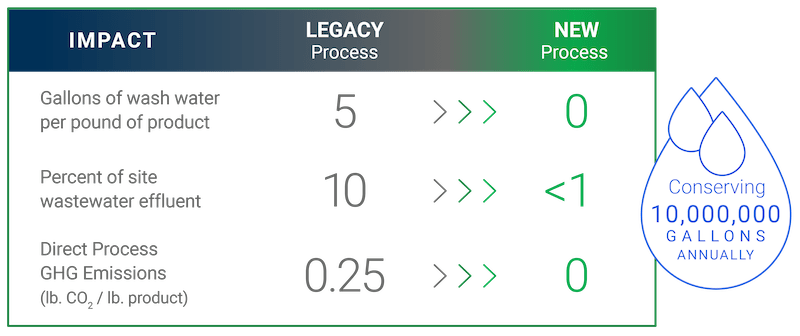

The legacy process used five gallons of water per pound of product. This, in turn, placed a strain on the wastewater treatment system. The new process is more sustainable, removing many of the resource-intensive steps.

By eliminating the need for extensive washing, the new process conserves water and reduces waste. More specifically, this process breakthrough is responsible for conserving over 10 million gallons of water annually.

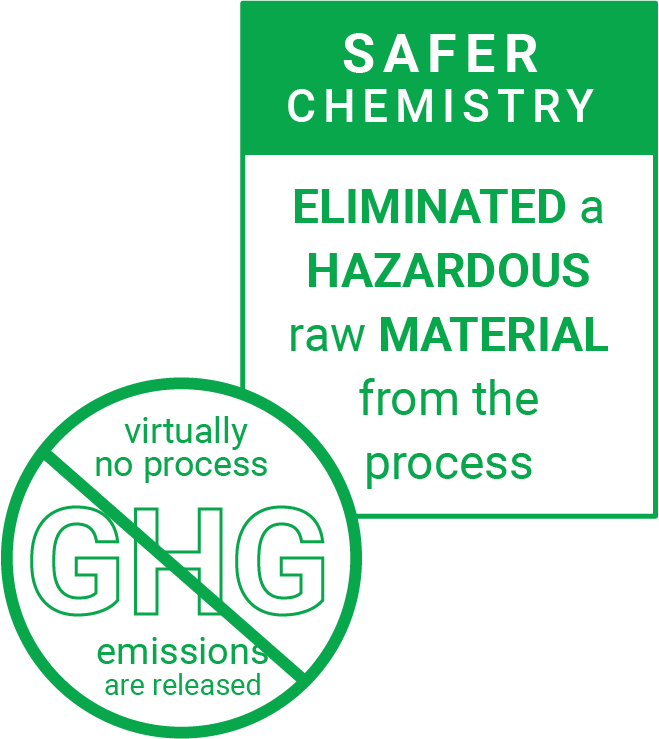

Additionally, the new process requires fewer chemicals and results in reduced waste products, offering a more efficient and eco-friendly solution. The reengineered process has eliminated use of a hazardous raw material. Furthermore, this change in reaction chemistry enables a decrease in the greenhouse gas (GHG) emissions generated by the process. In the new process, virtually no process GHG emissions are released. When compared to the legacy manufacturing process, the team has removed 0.25 lbs. CO2 per pound of product produced.

In conclusion, the shift to the new process reflects a greater focus on sustainability. By reducing water usage, cutting down on waste production, and minimizing emissions, the new method enhances this product line’s environmental performance while promoting more sustainable manufacturing practices.

Shepherd Mirecourt

ENVIRONMENTAL CONTROL PROJECT

European regulations controlling the emission of volatile organic compounds (VOCs) into the atmosphere are increasingly restrictive. For industrial activities that generate VOCs, emissions must be appropriately controlled and, if necessary, treated efficiently.

To continue to comply with emission limit values, Shepherd Mirecourt has installed a VOC treatment station to reduce emissions. The emissions from the processes are channeled to the station and passed through a bed of activated carbon that adsorbs the VOCs. The carbon pellets have a porous structure and a very large surface area to which the VOCs will adhere.

When the activated carbon becomes loaded with VOCs and before it reaches saturation, the carbon bed is regenerated with steam desorption. The steam produced by the boiler dislodges the VOCs trapped in the pores. The mix of steam and VOCs is drained down the carbon tank, condensed and collected for disposal.

With the VOC station, the emissions measured in the stack (the final exhaust point) have been reduced drastically and remain below the daily average limit. On-site regeneration prevents frequent overseas supply of “fresh new” activated carbon pellets and was designed to use ECO Mode set up of the general heater during weekends to reduce energy consumption.

To continue to improve and reach lower emission values, a study of the emissions will be carried out in 2025. Once it is accomplished, further improvement will be to optimize the frequency of the regeneration cycle to reduce energy consumption and minimize wastewater generation.

protect

We are committed to health, safety & environmental responsibility.

We PROTECT our people by practicing SafeStart principles at work and home. And we PROTECT the environment by monitoring and reducing our carbon footprint with sustainable process design in New Product Development and through Responsible Care® Product Stewardship.

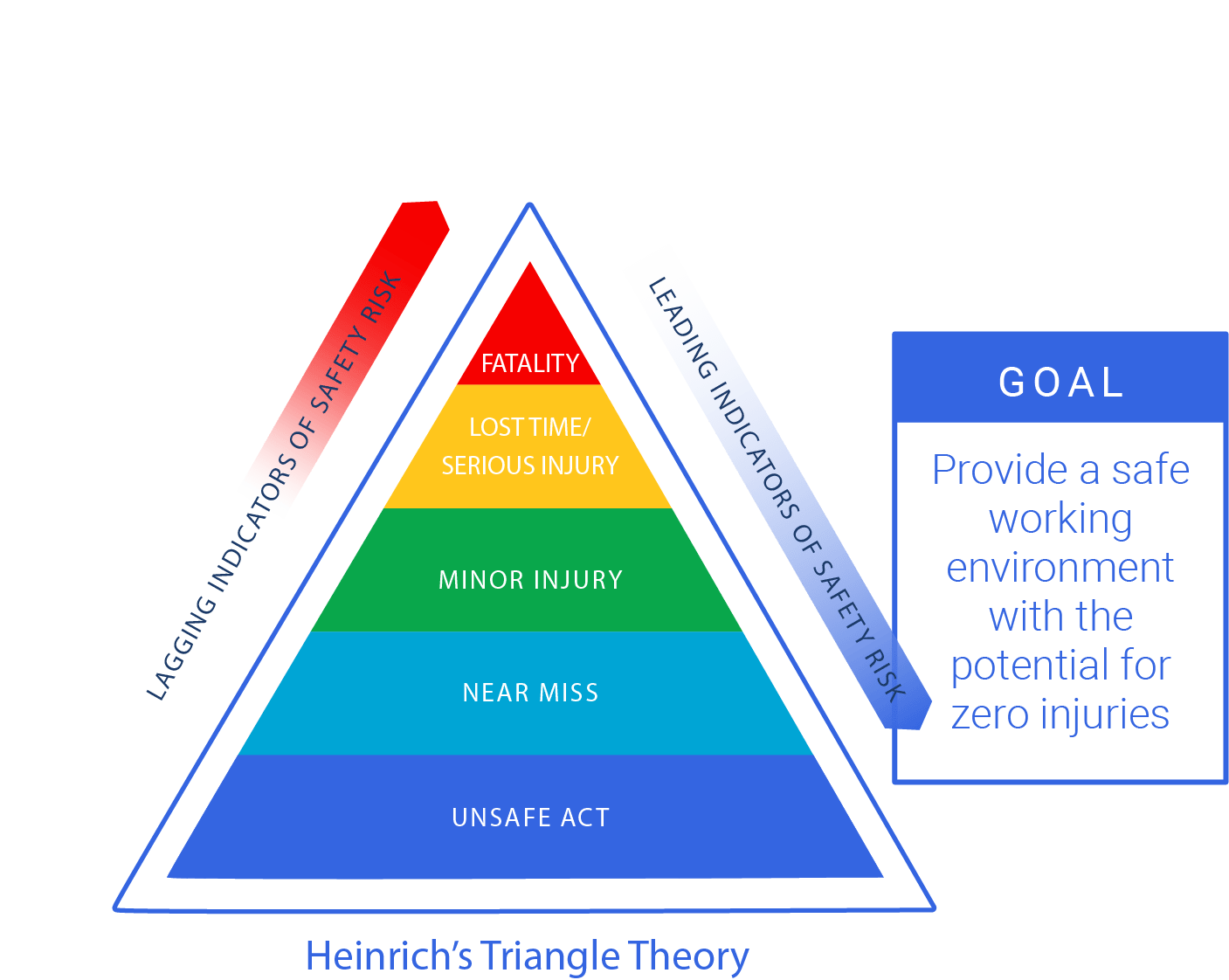

Protect Our People

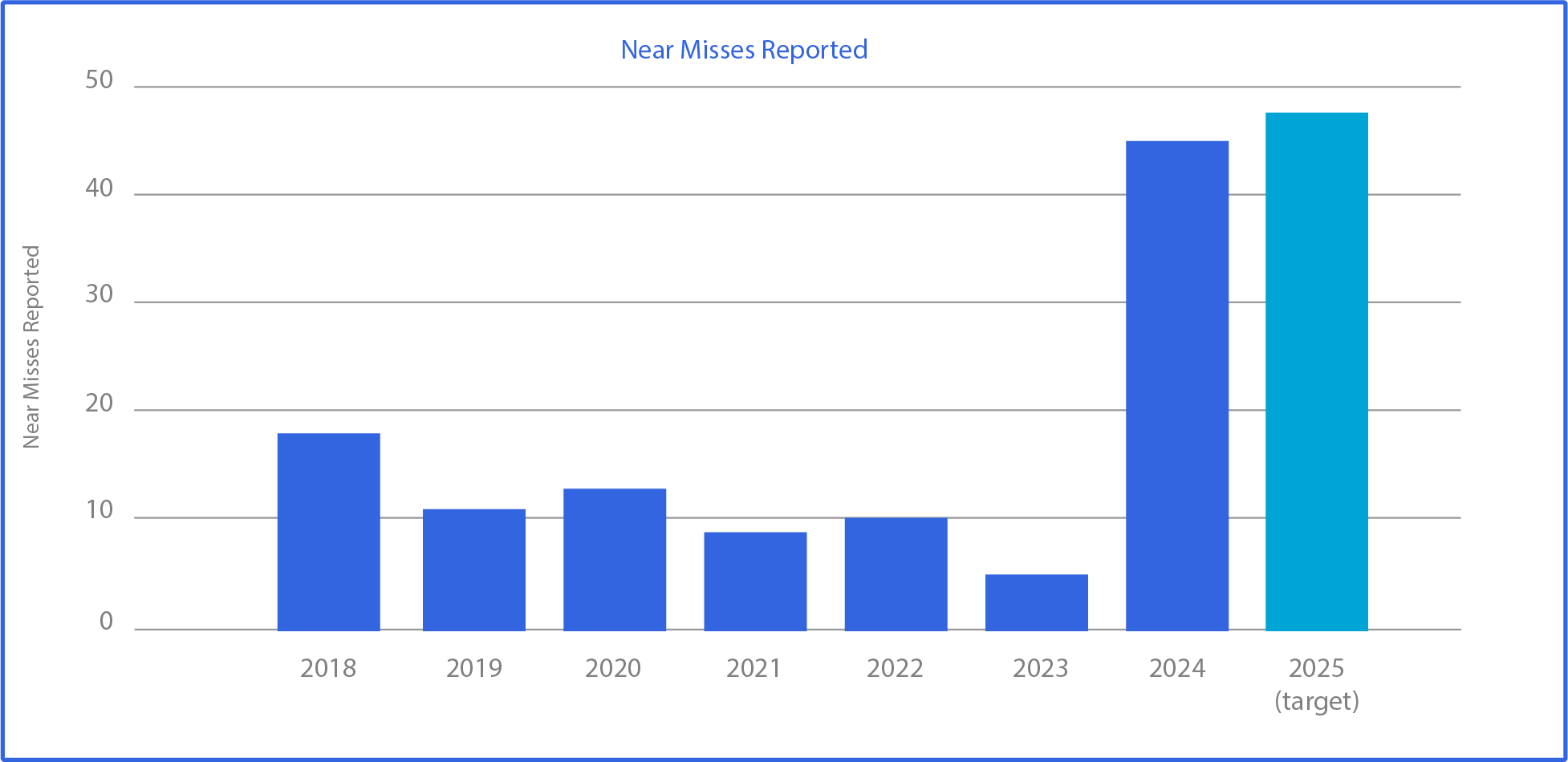

Near Miss Program

In 2024, Shepherd implemented a custom near miss reporting program across its US Operations. The goal of this program is to more proactively understand EHS&S and Quality performance and to implement preventive actions to address near misses. The program also aims to increase employee engagement with safety while decreasing the administrative workload for near misses.

This is accomplished by creating a simple near miss reporting form that takes only a few minutes to complete. The reporting form can be confidentially accessed by all employees on a computer or mobile device using a QR Code, allowing photo and file

attachments. Once a near miss is reported, an automatic notification is sent to the program manager, who will discuss

what happened and potential preventive actions with the reporting employee. Near misses are also reviewed by the EHS and

Quality teams and reported monthly to all managers and supervisors. Highlighted near misses are shared with the entire company bimonthly.

2024 Stats

Near miss submissions are analyzed to understand trends that go beyond any single event. All submissions are summarized and shared using a custom dashboard. Action items are tracked within this dashboard as well for accountability and transparency.

The program was rolled out using a company-wide online training program, communication in all-team meetings, and

Q&A opportunities with individual departments. The training was intended to clearly articulate the goal of the program and define a near miss.

As a result of this program, the company has become more successful at identifying and correcting insignificant events with the objective of preventing more serious incidents. Near miss reporting has increased sharply, from an average of 11 per year from 2018-2023 to 45 in 2024. Shepherd Chemical is excited to continue this momentum into 2025 and beyond.

SafeStart is a training program used to reduce incidents by decreasing the frequency of common states and human errors that increase the likelihood of such incidents.

At Shepherd, SafeStart has been baked into the culture for over a decade. The program includes regular company-wide training, sharing experiences, and competency checks through interactive team engagement. SafeStart provides a framework for reflection and self-awareness that can be used to reduce errors both at work and at home.

Protect Our Planet

Climate Impact

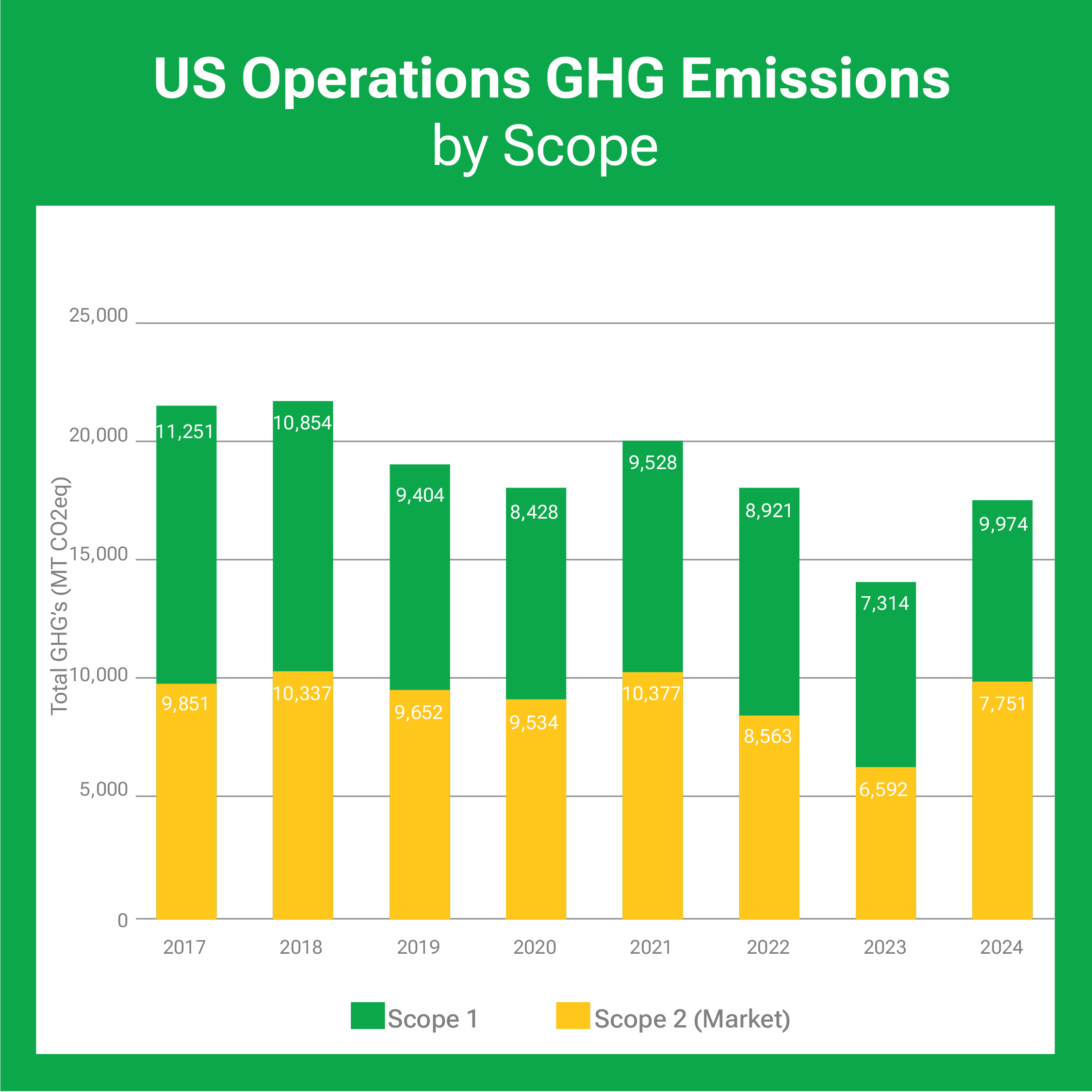

Shepherd’s climate program is based on the Greenhouse Gas (GHG) Protocol standards and guiding principles. The company currently tracks and reports on Scope 1 and Scope 2 emissions. Efforts are ongoing to understand and improve Scope 3 emissions, with a particular focus on Scope 3.1 (Purchased Goods and Services). These efforts are also informed by Together for Sustainability (TfS) and the GHG Protocol Scope 3 Standard. Shepherd also continues to develop a Product Carbon Footprint (PCF) database.

Scope 1 direct emissions include emissions of the Kyoto Protocol GHGs from fuels combusted on site, process emissions, and refrigerants. Scope 2 indirect emissions include purchased electricity. Shepherd uses the market-based approach for Scope 2 emissions due to its procurement of renewable electricity.

Climate Targets

Shepherd Chemical’s core purpose is to Create Value that Brightens Lives.

The company is committed to continually increasing the positive impact of its products and operations on society. Shepherd also commits to continually improving the environmental impact of its operations, including the impact on climate change. This will be accomplished through investments in operational efficiency and clean energy infrastructure, and through collaboration with supply chain partners.

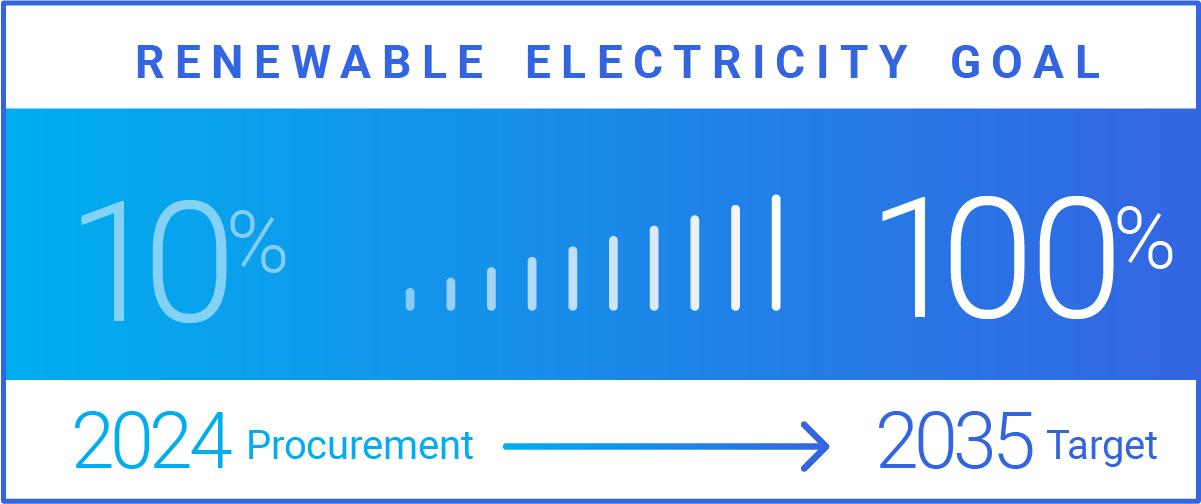

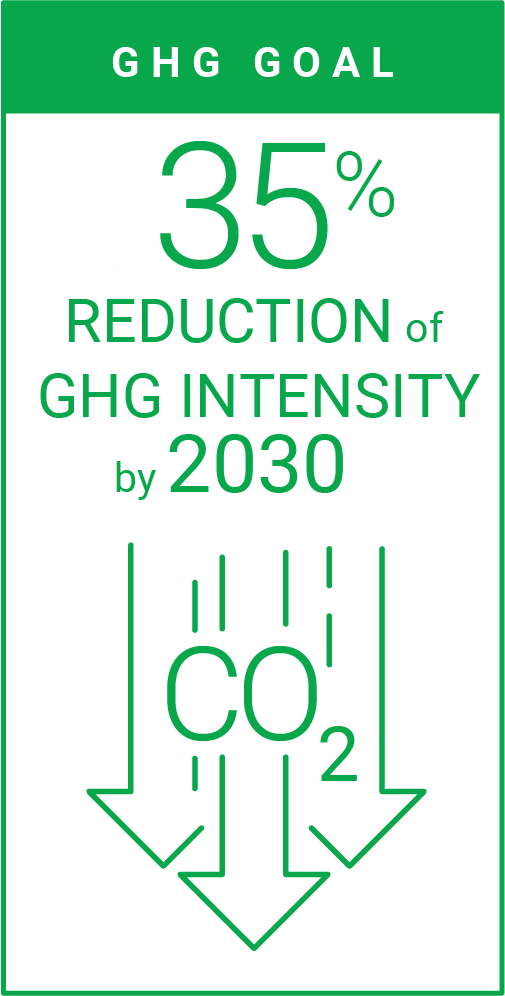

In 2024, Shepherd Chemical committed to its first quantitative greenhouse gas (GHG) emission reduction targets. The first of these goals is a reduction in the GHG emission intensity of US operations. This goal will drive improvements in climate impacts while supporting long-term business growth. The second goal is a commitment to increase procurement of green electricity. The long-term objective is to promote investments in clean energy infrastructure (both renewable and nuclear) to support society’s ever-increasing demand for electricity production.

contribute

We strive to do the right thing for sustainable metal chemistry by CONTRIBUTING positively to our communities and society by providing products that do good in the world, investing in and supporting education, and offering ongoing Physical, Social, Financial, and Community wellbeing programs for our team members.

Product Spotlight

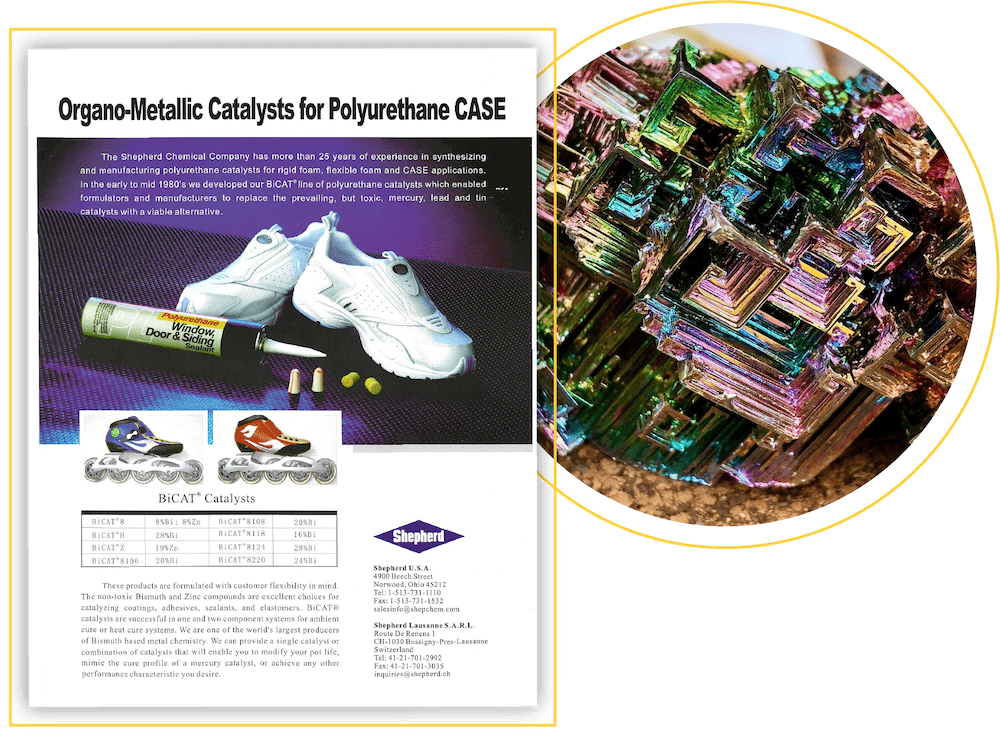

The Beauty of Bismuth

Shepherd has been one of the largest manufacturers of bismuth compounds for over 40 years. These compounds play a crucial role in advancing customers’ various industrial processes, acting as a safer alternative to other harmful heavy metals such as tin and lead. Bismuth boasts a unique set of properties, including a low melting point, diamagnetism, and even the ability to form organized iridescent oxide layers when recrystallized. It is not just a heavy hitter in the chemical industry though; it is also commonly used in medical devices and pharmaceuticals.

In addition to being a versatile additive for many industries, Shepherd’s bismuth carboxylates are mainly used as curative agents and cross linkers for polyurethanes. While tin-based catalysts have been widely used for decades in these applications, studies have shown bismuth carboxylates exhibit comparable catalytic activity to tin counterparts but with reduced environmental impact. Shepherd has continued to promote and lead the way in this new age of sustainable polyurethane production.

Other highlights include Bismuth Subcarbonate, which is used as a biocompatible x-ray opacifier that makes plastic tubing visible to surgeons during procedures. While the traditional option of barium sulfate is generally considered safe, its high density and insolubility can pose challenges in certain applications. Additionally, research is exploring the use of bismuth-based nanoparticles as contrast agents, which could offer improved imaging capabilities and reduced overall material usage.

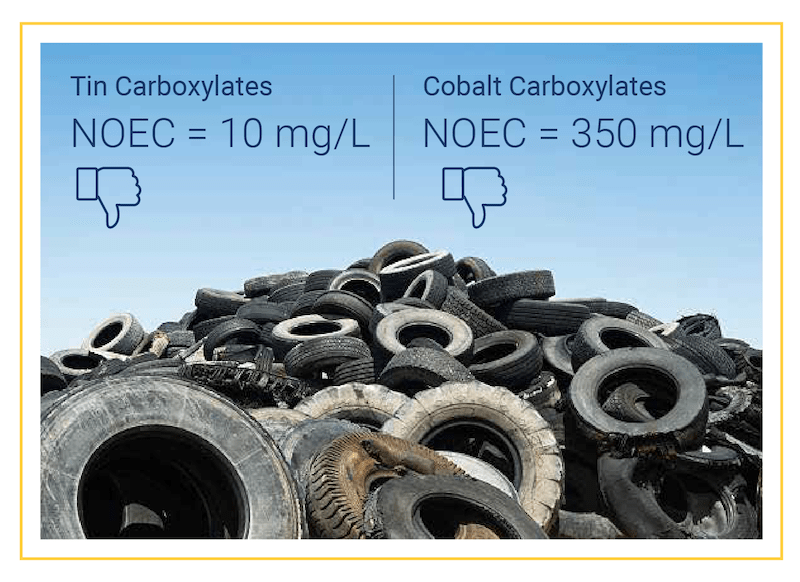

In automotive tire manufacturing, cobalt has remained the go-to when it comes to rubber adhesion promoters. Cobalt, while effective, has been linked to health and environmental risks and again, bismuth compounds can offer a less toxic alternative. Preliminary data suggests that Shepherd’s bismuth-based adhesion promoters can achieve comparable or even superior bond strength in rubber-to-metal applications. Considering the staggering amount of tire waste generated globally each year, bismuth-based adhesion promoters offer a pathway towards reducing used tires’ environmental impacts.

Bismuth’s lower toxicity offers comparable or superior performance in many applications and positions it as a safer, greener, next-generation heavy metal. Compared to the alternatives, Bismuth results in safer manufacturing processes and reduced environmental impact during disposal.

Community Engagement & Employee Experience

ADOPT-A-CLASS

Shepherd’s involvement in the community has always been a priority and the team remains committed to supplying local schools and organizations with high quality assistance and mentorship. One way Shepherd has achieved this is by sponsoring a classroom through the local non-profit organization Adopt-A-Class (ACC). AAC aims to connect businesses with underserved students in the greater Cincinnati area. The Adopt-A-Class program accomplishes this goal by pairing mentor teams with individual classrooms for an entire school year to allow mentor teams to continually expose students to range of life experiences that help broaden their awareness of future careers in their communities.

Since 2023, Shepherd’s mentor team has sponsored a 5th grade class from Sharpsburg Elementary right here in Norwood, Ohio. The team has worked hard to develop a monthly curriculum spanning the entire school year to explore numerous STEM topics and highlight the various vocations within the company. Examples of previous activities include solving a mystery escape room with puzzles to capture the essence of being a quality control chemist or capping off the year with them operating a ‘Mini-Chem Plant’, which lets them experience how an operator would actually run a chemical process.

While the program is ultimately centered around the students, it has also had a profound effect on its mentors by creating and cultivating a community within Shepherd focused on teamwork and social responsibility. Shepherd plans to support more classrooms in the future and continue to positively impact the next generation.

I want to help them (students) see their potential, even when the world might try to diminish it. Mentoring allows me to contribute to a future that’s driven by empathy and connection rather than indifference.

– Michael Vierheller

In AAC, we didn’t just tell students about our careers; we also described the personal traits that make us excel and enjoy our jobs. This connection helped students relate to careers through characteristics like problem-solving, logic, and curiosity. The goal was to make STEM fields seem attainable and inspire confidence in their potential success.

– Bethany Davies

At the end of the day, the volunteers feel a deep sense of fulfillment. Not only have they provided material support, but they have also given hope and a sense of community to those in need.

– Chris Frerick

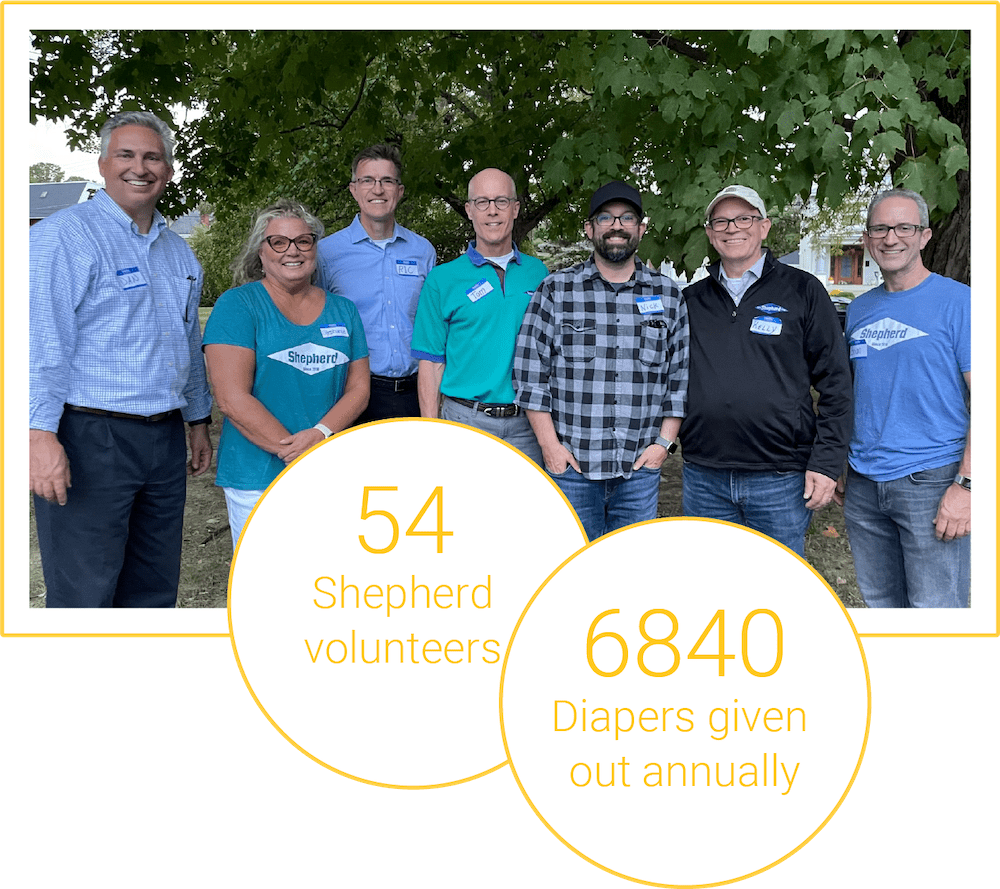

Baby Bear

Baby Bear is a community initiative in Norwood, Ohio, dedicated to supporting families with young children. Established in December 2018 by Stephanie Downs and Shepherd Material Science, Baby Bear hosts monthly events to provide essential items—such as clothing, toys, food, and diapers—to families in need.

These events take place at Grace and Truth Church in Cincinnati, where families can freely access the supplies they need, no questions asked. This open-door approach ensures that all families, regardless of their situation, can get the resources they require to care for their children.

The success of Baby Bear depends on the generosity of local residents and organizations. Donations are carefully organized and distributed at each event. In addition to the essentials, Baby Bear also offers a free meal to families, creating an opportunity for connection and support within the community. Beyond meeting immediate needs, Baby Bear fosters a warm, welcoming environment where parents and guardians can engage with others and share their experiences.

Thank You

Thank you for engaging with Shepherd Chemical’s inaugural sustainability report. In this next chapter of sustainability and innovation, Shepherd continues its longstanding pursuit of fulfilling its Core Purpose —

Creating Value that Brightens Lives

Disclaimer: The information contained in this report is for informational purposes only and does not create any legal rights or obligations. Readers are cautioned not to place undue reliance on past performance or forward-looking statements. Forward-looking statements are based on current assumptions and expectations, which are subject to risks and uncertainties that could cause actual results to differ materially from those projected. Inclusion of information in this report does not necessarily mean it is material to the company’s financial performance. Non-financial data included in this report is based on estimates and assumptions. This data is not subject to the same level of scrutiny as financial data and should be interpreted accordingly.

Scope: The Shepherd Chemical Company (“Shepherd”), a private company headquartered in Norwood, Ohio, U.S., prepared this sustainability report on a consolidated basis for U.S. operations, except where otherwise noted, which may include global operations. For Greenhouse Gas (GHG) emissions, Scope 3 is excluded.

Reporting Period: The report covers the 2024 calendar year, unless otherwise noted.

Trademarks, Trade Names, and Logos: All trademarks, trade names, and logos mentioned or used in this report are

the property of their respective owners.

Changes, Uncertainty, and Verification: While we strive to ensure the accuracy and completeness of the information in this report, it is subject to change and may not be exhaustive. We do not assume any liability for any errors or omissions. Changes to the scope of this report, corrections, base year changes, mergers, acquisitions, and divestitures, or significant methodology changes will be reported in the next edition of the sustainability report. An uncertainty analysis is currently not performed on the data included in this report. Data included in this report is currently not third-party assured or verified.

Contact us for additional information: sustainability@shepchem.com